What Is an NDT Vault? And Why Lead-Free Shielding Is Changing the Game

From submarines to smartphones, the most critical parts of modern life depend on products that are built to perform well under pressure. And when your business depends on catching flaws before they become failures, Non-Destructive Testing (NDT) is a critical part of the process.

Whether you’re inspecting a pipeline weld, a jet engine blade, or a medical implant, NDT helps manufacturers and engineers catch hidden flaws before they become costly — or dangerous. And for high-powered radiographic tests, that means working inside a purpose-built, shielded space known as an NDT vault.

Let’s break down what these vaults do, why NDT matters, and how Artemis Shielding’s lead-free materials are making the process smarter, safer, and more sustainable.

What Is Non-Destructive Testing?

Non-Destructive Testing is exactly what it sounds like: a way to inspect materials for cracks, voids, or other defects without compromising the item’s integrity. NDT is essential for:

- Product research & development: testing new materials or designs under simulated stress

- Quality control: catching internal defects like voids, cracks, or weld flaws

- Regulatory compliance: especially in sectors like aerospace, energy, nuclear, and defense

- Operational safety: preventing catastrophic failure in critical systems

Unlike destructive testing, which breaks or cuts a sample to analyze it, NDT preserves the item being tested through highly technical methods like ultrasonic, magnetic-particle, or eddy-current testing. Radiographic testing (RT), one of the most powerful NDT methods, uses X-rays or gamma rays to inspect inside dense materials. It’s incredibly effective but poses risks to people and the environment if not handled properly.

What’s an NDT Vault?

An NDT vault is a secure, shielded room designed to safely conduct radiographic testing. Inside, powerful radiation is used to scan the internal structure of components. Outside, no one should be exposed to that radiation — which is where shielding comes in.

These vaults are typically lined with dense shielding materials and outfitted with features like:

- Interlocking doors

- Radiation alarms

- Remote operation capabilities

Whether it’s inspecting microchips with 80kV portable units or testing nuclear ship components with 9MeV sources, the right vault ensures safety, compliance, and precision.

Why are NDT Vaults Used?

An NDT vault is a specially engineered room designed to safely contain high levels of ionizing radiation. Without proper shielding:

- Workers can be exposed to ionizing radiation, increasing the risk of long-term health effects including cancer and organ damage.

- Surrounding environments (including soil and water) can become contaminated, especially if lead or radioactive materials leak.

- Facility compliance may be compromised, risking fines, shutdowns, and damage to public trust.

Traditional shielding materials like lead offer strong protection — but they’re heavy, toxic, and difficult to dispose of responsibly. Improper handling during construction or demolition can pose major health and environmental threats.

Traditional Shielding: Heavy on Weight, Light on Sustainability

Historically, NDT vaults have relied on lead-lined steel or thick concrete to block radiation. And while effective, these materials come with trade-offs:

- Excessive weight and space demands

- Difficult and expensive installation

- Toxicity concerns and environmental risks

As testing needs evolve — and sustainability regulations tighten — many companies are rethinking their shielding strategies.

The Artemis Shielding Advantage

Artemis Shielding offers a smarter, cleaner alternative. Our Nanotek® and XYZ-Pure™ materials are lead-free, non-toxic, and fully customizable, delivering high-performance shielding without the downsides.

Key benefits include:

- Exceptional radiation attenuation across a wide range of applications, from 80kV electronics inspections to 100Mev nuclear vaults.

- Reduced weight and footprint, which can lower construction and installation costs.

- RoHS and Cal Prop 65 compliance, supporting safer workplaces and a greener planet.

- Fully customizable designs to fit any vault shape, size, or shielding requirement.

These materials are already being used in NDT vaults across sectors like defense, energy, aerospace, and electronics, helping companies build a safer testing environment without compromising sustainability goals.

Safer Shielding for a Smarter Future

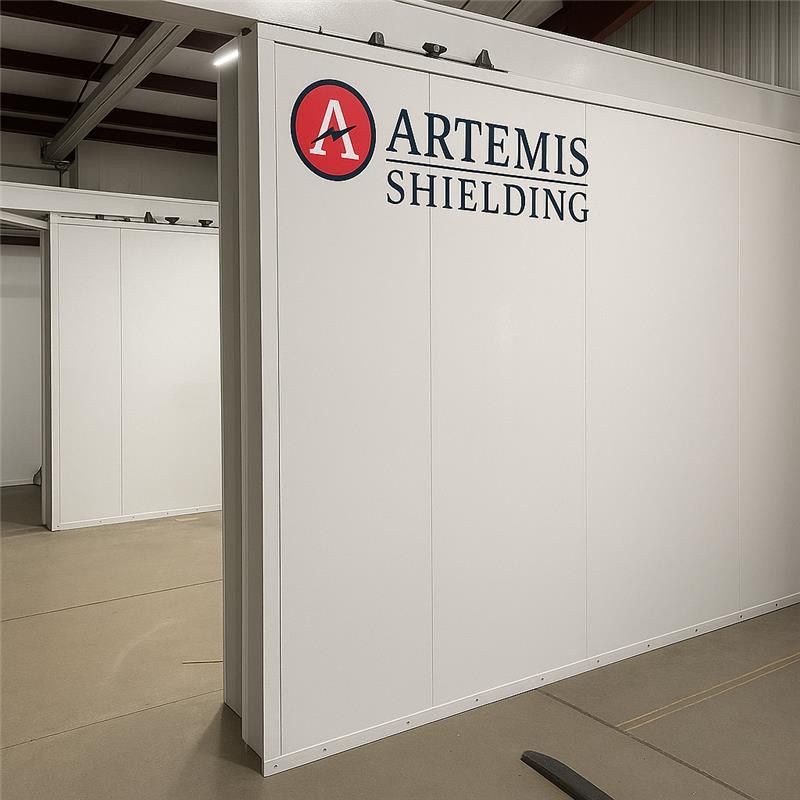

As Artemis Shielding continues to raise the bar with advanced NDT vault solutions, our recent vault installation is just one more example of how innovation, safety, and sustainability can work together.

Ready to upgrade your NDT protection?

Contact Artemis Shielding to learn more about custom, lead-free radiation shielding for your next testing facility.